MachineToolSpares

Spares for HMT (CONVENTIONAL/CNC), MYSORE KIRLOSKAR, LINEAR GUIDEWAYS, TAPPING ATTACHMENTS. Circular Saw Blades and M42 Band Saw Blades Our product range, carefully designed down to the minutest detail and using ultra-modern machinery.

The demands placed on metal cutting operations are becoming ever more stringent. The company’s cooperation with research institutes, users and manufacturers of cutting materials and sawing machines is likely to lead to innovations even in the near future, particularly in the carbide section, to ensure optimal high-performance metal cutting operations Segmental Circular Saw Blades

Update: March2008

| Standardprogram: Designs and Dimensions in HSS S-6-5-2 (DMo5) |

| Ø D |

Cutting width ap |

Blade Thickness S |

Weight per Blade |

No of segments |

Standard Centre Bore HB and Pinholes NL |

Pitch T at no of teeth per segment [mm] |

| [mm] |

[mm] |

[mm] |

[kg] |

[Stck] |

HB NL Stck/ Ø /Teilkreis Ø |

2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

| 250 |

3, 0 |

2, 4 |

1, 0 |

12 |

32 4/9/50 + 2/12/64 40 2/8, 5/55 + 4/12/64 |

|

21, 8 |

16, 4 |

13, 1 |

10, 9 |

8, 2 |

6, 5 |

5, 5 |

| 275 |

3, 0 |

2, 4 |

1, 1 |

12 |

40 2/8, 5/55 + 4/12/64 |

|

24, 0 |

18, 0 |

14, 4 |

12, 0 |

9, 0 |

7, 2 |

6, 0 |

| 300 315 |

3, 6 |

3, 0 |

1, 6 1, 8 |

14 |

40 2/8, 5/55 + 4/12/64 |

|

22, 4 23, 6 |

16, 8 17, 7 |

13, 5 14, 1 |

11, 2 11, 8 |

8, 4 8, 8 |

6, 7 7, 1 |

5, 6 5, 9 |

| 360 |

3, 6 |

3, 0 |

2, 4 |

16 |

40 2/8, 5/55 + 4/12/64 50 4/15/80 + 4/15/85 |

|

23, 6 |

17, 7 |

14, 1 |

11, 8 |

8, 8 |

7, 1 |

5, 9 |

| 370 |

3, 6 |

3, 0 |

2, 6 |

16 |

50 4/15/80 + 4/15/85 |

|

24, 2 |

18, 2 |

14, 5 |

12, 1 |

9, 1 |

7, 3 |

6, 1 |

| 400 400 |

4, 0 5, 0 |

3, 3 3, 5 |

3, 0 3, 3 |

16 |

50 4/15/80 + 4/15/85 |

|

26, 2 |

19, 6 |

15, 7 |

13, 1 |

9, 8 |

7, 9 |

6, 5 |

| 410 |

5, 0 |

3, 5 |

3, 4 |

18 |

50 4/15/80 + 4/15/85 |

|

23, 8 |

17, 9 |

14, 3 |

11, 9 |

8, 9 |

7, 2 |

6, 0 |

| 425 |

4, 0 |

3, 0 |

3, 3 |

18 |

50 4/15/80 + 4/15/85 |

|

24, 7 |

18, 5 |

14, 8 |

12, 4 |

9, 3 |

7, 4 |

6, 2 |

| 450 |

4, 0 |

3, 3 |

4, 1 |

18 |

40 2/15/80 + 2/15/100 50 4/15/80 + 4/18/100 |

|

26, 2 |

19, 6 |

15, 7 |

13, 1 |

9, 8 |

7, 9 |

6, 5 |

| 460 |

5, 0 |

3, 5 |

4, 6 |

18 |

50 4/15/80 + 4/15/85 60 4/16/90 + 4/23/96 60 4/18/100 |

|

26, 7 |

20, 1 |

16, 0 |

13, 4 |

10, 0 |

8, 0 |

6, 7 |

| 510 |

5, 7 |

4, 0 |

6, 5 |

18 |

50 4/18/100 50 4/15/80 + 4/18/100 |

|

29, 7 |

22, 2 |

17, 8 |

14, 8 |

11, 1 |

8, 9 |

7, 4 |

| 560 |

5, 0 |

3, 7 |

7, 0 |

18 |

50 4/18/100 80 8/22/142 |

|

32, 6 |

24, 4 |

19, 5 |

16, 3 |

12, 2 |

9, 8 |

8, 1 |

| 630 |

5, 0 |

3, 8 |

9, 0 |

20 |

80 4/22/120 + 4/27/160 |

49, 5 |

33, 0 |

24, 7 |

19, 8 |

16, 5 |

12, 4 |

9, 9 |

8, 2 |

| 630 |

6, 0 |

4, 5 |

11, 0 |

20 |

80 4/22/120 + 4/27/160 |

49, 5 |

33, 0 |

24, 7 |

19, 8 |

16, 5 |

12, 4 |

9, 9 |

8, 2 |

| 660 |

6, 0 |

4, 5 |

12, 0 |

20 |

80 4/22/120 + 4/27/160 80 8/22/142 |

51, 8 |

34, 5 |

25, 9 |

20, 7 |

17, 3 |

13, 0 |

10, 4 |

8, 6 |

| 710 |

6, 2 |

4, 5 |

14, 0 |

24 |

80 4/22/120 + 4/27/160 |

46, 4 |

31, 0 |

23, 2 |

18, 6 |

15, 5 |

11, 6 |

9, 3 |

7, 7 |

| 760 |

6, 3 |

4, 5 |

16, 0 |

24 |

80 4/22/120 + 4/27/160 |

49, 7 |

33, 1 |

24, 9 |

19, 9 |

16, 6 |

12, 4 |

9, 9 |

8, 3 |

| 810 |

6, 8 |

5, 0 |

20, 0 |

24 |

80 4/22/120 + 4/27/160 |

53, 0 |

35, 3 |

26, 5 |

21, 2 |

17, 7 |

13, 2 |

10, 6 |

8, 8 |

| 860 |

6, 5 |

4, 5 |

20, 5 |

24 |

80 4/22/120 + 4/27/160 |

56, 3 |

37, 5 |

28, 1 |

22, 5 |

18, 8 |

14, 1 |

11, 3 |

9, 4 |

| 910 920 960 |

7, 0 |

5, 0 |

26, 0 27, 0 29, 0 |

30 |

80 4/22/120 + 4/27/160 100 8/27/186 100 4/32/200 |

47, 6 48, 1 50, 2 |

31, 7 32, 1 33, 5 |

23, 8 24, 1 25, 1 |

19, 5 19, 3 20, 1 |

15, 9 16, 0 16, 7 |

11, 9 12, 0 12, 6 |

9, 5 9, 6 10, 0 |

7, 9 8, 0 8, 4 |

| 1010 1110 |

8, 0 |

6, 0 |

38, 0 45, 0 |

30 36 |

100 4/32/200 + 4/32/250 |

52, 9 48, 4 |

35, 2 32, 3 |

26, 4 24, 2 |

21, 1 19, 4 |

17, 6 16, 1 |

13, 2 12, 1 |

10, 6 9, 7 |

8, 8 8, 1 |

| 1120 |

8, 2 |

6, 0 |

46, 0 |

36 |

100 4/32/200 + 4/32/250 |

48, 8 |

32, 6 |

24, 4 |

19, 5 |

16, 3 |

12, 2 |

9, 8 |

8, 1 |

| 1250 |

9, 0 |

7, 0 |

67, 0 |

36 |

100 4/32/250 |

54, 5 |

36, 3 |

27, 3 |

21, 8 |

18, 2 |

13, 6 |

10, 9 |

9, 1 |

| 1310 1320 |

9, 0 |

7, 0 |

74, 0 75, 0 |

36 |

100 4/32/250 |

57, 1 57, 6 |

38, 1 38, 4 |

28, 6 28, 8 |

22, 9 23, 0 |

19, 0 19, 2 |

14, 3 14, 4 |

11, 4 11, 5 |

9, 5 9, 6 |

| 1320 |

6, 7 |

5, 2 |

55, 0 |

36 |

100 4/32/250 |

57, 6 |

38, 4 |

28, 8 |

23, 0 |

19, 2 |

14, 4 |

11, 5 |

9, 6 |

| 1410 |

9, 0 |

7, 0 |

86, 0 |

36 |

100 4/32/250 |

61, 5 |

41, 0 |

30, 7 |

24, 6 |

20, 5 |

15, 4 |

12, 3 |

10, 2 |

| 1430 |

9, 5 |

7, 0 |

88, 0 |

36 |

100 4/32/250 |

62, 4 |

41, 6 |

31, 2 |

24, 9 |

20, 8 |

15, 6 |

12, 5 |

10, 4 |

| 1510 |

9, 0 |

7, 0 |

98, 0 |

36 |

100 4/32/250 |

65, 9 |

43, 9 |

32, 9 |

26, 3 |

22, 0 |

16, 5 |

13, 2 |

11, 0 |

| 1610 |

11, 0 |

8, 0 |

128, 0 |

40 |

100 4/33/315 |

63, 2 |

42, 1 |

31, 6 |

25, 3 |

21, 1 |

15, 8 |

12, 6 |

10, 5 |

| Further Designs and Dimensions like other cutting material S-6-5-2-5 (EMo5Co5), different centre bore and pinhole combinations are available upon request. | Carbide Tipped Circular Blades

Stand: 04 / 97

| Standard: up to 2200 mm diameter |

| diameter Æ |

cuttingwidth |

number of teeth X ^= standard |

| mm |

mm |

30 |

34 |

40 |

48 |

50 |

54 |

60 |

70 |

80 |

90 |

100 |

110 |

120 |

130 |

140 |

160 |

180 |

200 |

| 220 |

4, 0 |

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 315 |

4, 0 |

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

| 350 |

4, 0 |

|

|

X |

|

X |

|

X |

X |

|

|

|

|

|

|

|

|

|

|

| 400 |

5, 0 |

|

|

X |

X |

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

|

| |

3, 6 |

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 420 |

5, 0 |

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 475 |

5, 0 |

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

| 500 |

5, 5 |

|

|

|

|

X |

|

X |

X |

|

|

|

|

|

|

|

|

|

|

| 560 |

3, 6 |

|

|

X |

|

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

|

| 570 |

5, 5 |

|

|

|

|

|

|

X |

|

|

|

X |

|

|

|

|

|

|

|

| 610 |

6, 5 |

|

|

|

|

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

| 630 |

6, 5 |

|

|

X |

|

X |

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

| |

3, 8 |

|

|

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

| 660 |

6, 5 |

|

|

|

|

|

X |

X |

X |

X |

X |

|

|

|

|

|

|

|

|

| 710 |

6, 5 |

|

|

X |

|

X |

X |

X |

X |

X |

X |

X |

|

|

|

|

|

|

|

| 810 |

7, 5 |

|

|

X |

|

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

|

| 830 |

7, 5 |

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

| 860 |

7, 5 |

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

| 910 |

8, 0 |

X |

|

|

|

X |

|

X |

X |

X |

|

X |

|

X |

|

X |

|

|

|

| 1010 |

8, 5 |

|

|

X |

|

X |

|

X |

X |

|

|

|

|

X |

|

X |

|

|

|

| 1120 |

8, 5 |

|

|

|

|

X |

|

X |

|

|

|

|

|

|

X |

|

|

|

|

| 1160 |

8, 5 |

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

| 1250 |

11, 0 |

|

|

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

| 1430 |

12, 0 |

|

|

|

|

X |

X |

X |

|

|

X |

|

X |

|

|

|

|

|

|

| 1530 |

12, 5 |

|

|

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

| 1600 |

12, 5 |

|

|

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

X |

X |

| 1650 |

12, 5 |

|

|

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

| 1850 |

12, 5 |

|

|

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

| Additional sizes and numbers of teeth are supplied as per your request. (When ordering please state bore specification) | Circular Hot and Friction Saw Blades

Hot and Friction Saw Blades up to 2500 mm diameter are tools of high efficiency made from well proven steel plates with a tensile strenght of 850 bis 950 N/mm 2.

Hot and friction saw blades are used for cutting: slabs - square billets - plates - tubes - profiles

Hot saw blades are used to cut metals with a temperature in excess of 850° C. When sawing metals below a temperature of 250° C, friction saw blades are used.

Both sawing methods are a friction cutting. The friction heat in the cutting gap a e produces temperatures which bring the material in a soft, almost plastic condition. In order to clear debris from the tooth gullet a copiuos or heavy flow of coolant (preferably under high pressure) is essential for efficient cutting. The required cutting speed is Vc=100-140 m/sec.

Depending on the material to be cut the feed reached is Vf=80-2000 mm/min. The tooth geometry and tooth pitch are determined by the section and quality (analysis) of the material to be cut and the sawing machine.

Heat treatment of the saw blades of 1200-1250 N/mm² (up to 1000 mm diameter) or hardening of the teeth up to Rockwell C 58 (up to 2500 diameter) gives an increase in both blade life and in number of cuts between resharpening.

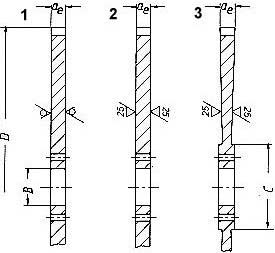

| Designs: |

|

|

D = Diameter of Saw Blade

Æ = Cutting gap = kerf (mm)

B = Diameter of center bore

C = Diameter of flange

Design 1: black rolled

Design 2: face ground

Design 3: taper ground |

Bi-Metal Band Saw Blades

Stand: 04 / 97

| Dimensions: Bi-Metal Band Saw Blades * |

Dimension (mm)

width x thickness |

Teeth per inch with tooth form S, K, C |

| mm |

0, 75 |

1, 25 |

2 |

3 |

4 |

6 |

8 |

10 |

14 |

1/2 |

2/3 |

3/4 |

4/6 |

5/8 |

6/10 |

8/12 |

10/14 |

| |

Quality M 42 |

| 6 x 0, 9 |

|

|

|

|

|

K |

|

S |

S |

|

|

|

|

|

|

|

|

| 10 x 0, 9 |

|

|

|

|

K |

K |

|

S |

S |

|

|

|

|

|

|

|

|

| 13 x 0, 9 |

|

|

|

|

K |

K |

|

S |

S |

|

|

|

|

|

|

|

|

| 20 x 0, 9 |

|

|

|

K |

S |

S |

S |

S |

S |

|

|

|

C |

C |

C |

C |

C |

| 27 x 0, 9 |

|

|

K |

K |

S |

S |

S |

S |

S |

|

C |

C |

C |

C |

C |

C |

C |

| 34 x 1, 1 |

|

K |

K |

K |

S |

S |

S |

|

|

|

C |

C |

C |

C |

C |

C |

|

| 41 x 1, 3 |

|

K |

K |

K |

S |

|

|

|

|

|

C |

C |

C |

C |

|

|

|

| 54 x 1, 3 |

|

K |

K |

K |

S |

|

|

|

|

|

C |

C |

C |

|

|

|

|

| 54 x 1, 6 |

|

K |

K |

K |

|

|

|

|

|

C |

C |

C |

C |

|

|

|

|

| 67 x 1, 6 |

K |

K |

K |

|

|

|

|

|

|

C |

C |

|

|

|

|

|

|

| 80 x 1, 6 |

K |

K |

K |

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

| |

Quality M 51 |

| 34 x 1, 1 |

|

|

K |

K |

S |

|

|

|

|

|

C |

|

|

|

|

|

|

| 41 x 1, 3 |

|

|

K |

K |

|

|

|

|

|

|

C |

C |

|

|

|

|

|

| 54 x 1, 6 |

|

K |

K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 67 x 1, 6 |

K |

K |

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

| 80 x 1, 6 |

K |

K |

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

| * Band Saw Blades are available in coils of 30-50-75-100 m or welded to length. |

| Dimensions: Carbon Steel Band Saw Blades** |

| Dimension (mm) width x thickness |

Teeth per inch with tooth form S, K, L |

| mm |

2 |

3 |

4 |

6 |

7 |

8 |

10 |

14 |

18 |

22 |

32 |

| |

Quality CS |

| 4 x 0, 65 |

|

|

|

|

|

S |

S |

S |

S |

S |

S |

| 5 x 0, 65 |

|

|

|

|

|

S |

S |

S |

S |

S |

S |

| 6 x 0, 65 |

|

|

S K L |

S K |

L |

S |

S |

S |

S |

S |

S |

| 8 x 0, 65 |

|

|

S K L |

S K |

S L |

S |

S |

S |

S |

S |

S |

| 10 x 0, 65 |

|

|

S K L |

S K |

S L |

S |

S |

S |

S |

S |

S |

| 13 x 0, 65 |

|

S K L |

S K L |

S |

S L |

S |

S |

S |

S |

S |

S |

| 16 x 0, 80 |

|

S K L |

S K L |

S K |

S L |

S |

S |

S |

S |

S |

S |

| 20 x 0, 80 |

|

S K L |

S K L |

S K |

S L |

S |

S |

S |

S |

S |

S |

| 25 x 0, 90 |

|

S K L |

S K L |

S K |

S L |

S |

S |

S |

S |

S |

|

| |

Quality CS Plus |

| 4 x 0, 65 |

|

|

|

|

|

|

S |

|

S |

S |

|

| 6 x 0, 65 |

|

|

K |

S K |

|

S |

S |

S |

S |

S |

S |

| 8 x 0, 65 |

|

|

K |

S K L |

|

S |

S |

S |

S |

S |

|

| 10 x 0, 65 |

|

|

S K |

S K L |

|

S |

S |

S |

S |

S |

|

| 13 x 0, 65 |

|

|

S K L |

S K L |

S |

S |

S |

S |

S |

S |

S |

| |

Quality TS |

| 16 x 0, 80 |

|

|

S K |

S K |

|

S |

S |

S |

S |

S |

|

| 20 x 0, 80 |

|

S K |

S K |

S K |

|

S |

S |

S |

S |

S |

|

| 25 x 0, 90 |

|

S K L |

S K |

S K |

|

S |

S |

S |

|

S |

|

| ** Band Saw Blades are available in coils of 30 m or welded to length. For horizontal and vertical band saw machines. Additional sizes on request. Technical data subject to modification. | |